ALD

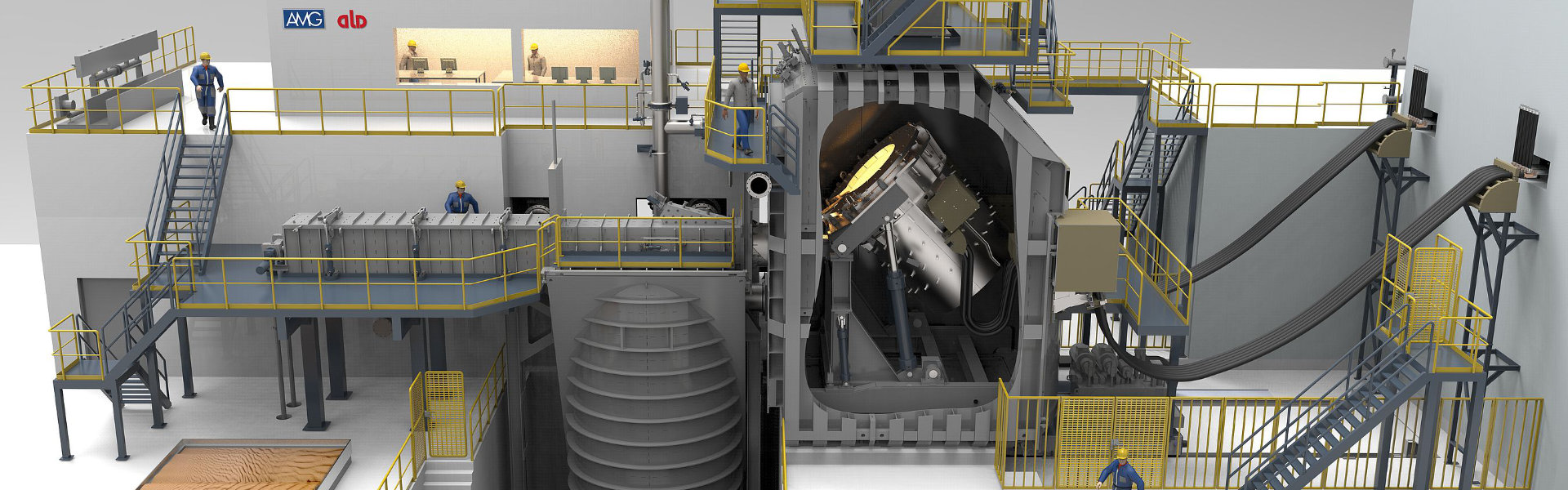

ALD Vacuum Technologies GmbH is the world's leading manufacturer of vacuum technology systems in the field of metallurgy and heat treatment. ALD sets standards with innovative products, state-of-the-art technology, comprehensive service and maximum flexibility.

Industry: Plant/mechanical engineering

Locations: Locations in

10 countries

Operating performance 2019: € 181 million

Operating performance 2020: €147 million

Employees: 900 employees

"With clevercure, we avoid system breaks and thus reduce non-value-adding activities to a minimum."

Albrecht Höfler, Vice President Procurement ALD Vacuum Technologies GmbH

Our path to an end-to-end supply chain

ALD Vacuum Technologies GmbH, based in Hanau near Frankfurt, has set itself the goal of an end-to-end digital supply chain. Read the interview with Albrecht Höfler, Vice President Procurement at ALD, to find out what other companies can learn from his strategic considerations.

Mr. Höfler, what was the main reason for launching an end-to-end digital supply chain project? What was and is your vision in this context?

Our vision of a "digital supply chain" should become a reality. However, this is not an end in itself, but to increase the efficiency of the purchasing organization. The aim is to avoid system breaks, which are the number one source of errors in the purchasing organization as in any other organizational unit, and to reduce administrative and therefore non-value-adding activities to a minimum. Increasing transparency in processes and prices should also be achieved.

What were your steps towards the digital supply chain?

The first step was to make more extensive use of SAP functionalities for determining requirements and order specifications as a starting point for seamless interaction and integration with our SRM system from curecomp, so that not just a few large or important suppliers, but many suppliers could be connected with regard to all procurement processes. For the smaller suppliers in particular, it was crucial for us that the system is easy and intuitive for the suppliers' users to operate. With the "BANF-Cockpit" from clevercure, we were able to implement an end-to-end "BANF-to-Pay" process.

What new opportunities have you created internally and externally by using the clevercure solution?

In addition to the increase in efficiency and reduction in workload through the operational connection of suppliers, we rely on structured and standardized workflows that we can now design independently - without the help of external consultants - completely freely and variably. This brings transparency to our internal processes and we are automatically reminded by the system if an action is required or due. Now our employees can focus on procurement and not on their "administration". With these workflows, we are now also overcoming the boundaries between internal and external participants in the respective processes. To "protect" the suppliers, they are only actively involved in the respective processes on an "event-related" basis. This means that these external participants have no additional work involved in registering and monitoring any to-dos in a portal, which has been very well received.

Control and overview of the "digital supply chain" - how does this work at ALD?

At ALD, control and monitoring are now carried out in particular via dashboards that users can design themselves, as well as an active reporting system for clevercure to the responsible purchasers. In this way, we ensure that users have the relevant information available to them at a glance. By integrating data across system boundaries, data from external systems was integrated into these dashboards, as it is not the purchasers' job to laboriously collect the data, but to interpret it.

What were the most important factors in your decision to opt for curecomp's clevercure solution?

We wanted a flexible solution that would allow users to design processes, workflow structures and data structures independently and change them as required, without always needing external advice. This gives us great flexibility when making process changes while at the same time controlling our costs. As a medium-sized company, it was also important for us to choose a partner that was right for us and with whom we could work in partnership, in a goal-oriented manner and on an equal footing. Our experience with the competent team at curecomp has been very positive.

What is your assessment of the expectations and the results achieved?

We have been productive with the first modules for a few months now, are in the middle of the roll-out to suppliers and are also much better organized and more transparent internally with many workflows. We have therefore achieved what we set out to do. We want to push ahead with the roll-out to suppliers so that we can take advantage of the resulting increase in efficiency in the near future.

What are the next steps on your path to the "digital supply chain"?

The next clevercure modules to be implemented are a catalog module in the operational area and the supplier evaluation module in the strategic area. In our view, the digitalization of the supply chain is not a one-off project, but a more modern approach in line with the motto "standing still is a step backwards".

What can you recommend to other companies that want to implement a similar project to ALD?

The preparation and involvement of all colleagues concerned is essential to ensure the acceptance and success of such a project. The solution partner should and must offer a standard solution that also offers flexibility for individual process changes without you having to pay for every change to a field or additional data structures, etc. With the clevercure solution from curecomp, we had found the right partner for "Digital Supply Chain".

Do you have any questions? We'll show you the right way.

Get in touch with us today and find out how similar companies are significantly improving their purchasing processes.

This is how you can create real added value right from the supplier application stage!

We will show you, free of charge and with no obligation, how you can take your supplier management to a whole new level with clever automation.